Welding & Thermal Spray Coatings

DutyServe, Inc has great pride in our weld and hard coating experience, having that been one of our cornerstones for over 50 years. Using multiple different weld and thermal spray processes and state-of-the-art equipment, our "weld artists" can tackle multiple different applications with the utmost accuracy and speed. At the very heart of the weld and thermal spray division is the expert ability to work with all types of materials, alloys, hard facings, and heat treatments, along with engineering-backed advisory to the client suggesting how we can extend the life of critical equipment and parts using hard facing weld overlays and thermal spray reducing client's downtime and costs. Precision welds & coatings on critical, high-dollar, long lead-time equipment and parts are our specialty, and we look forward to assisting you with any challenge that may arise.

Here's some of the different weld & spray processes used:

DutyServe, Inc can weld & spray a variety of metals, alloys, & hard facings including:

Stellite

Tungsten Carbide

Hard Chrome

Chrome Carbide

Colmonoy

Inconel

Incolloy

Hastelloy

Monel

Titanium

Tantalum

Ceramics

Super Duplex Stainless Steel

Aluminum

Bronze

Copper

All Grades of Stainless Steel & Ferrous Alloys

TIG-Gas Tungsten Arc Welding (GTAW)

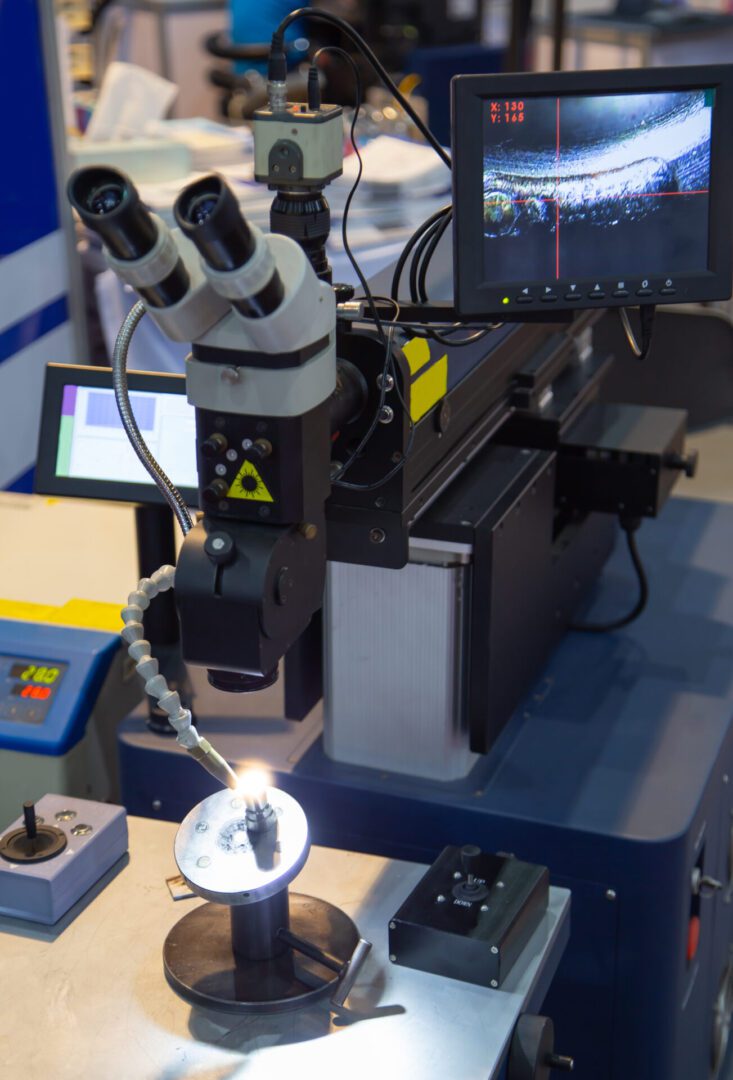

Microscopic TIG Welding

Plasma Transferred Arc Welding (PTA)

MIG-Gas Metal Arc Welding (GMAW)

Laser Beam Welding

Electron Beam Welding

Stick Welding-Shielded Metal Arc Welding

HVOF-High Velocity Oxy Fuel Spraying

Plasma Spraying

Flame Spray

Stellite Overlay

Microscopic Welding